ELECTRONICS DEVELOPMENT

Krüger & Gothe GmbH specializes in the production of complex electronic products in small, medium and large series. From order management and material procurement to complete production, including comprehensive testing, the company covers the needs of its customers. Many years of experience in all segments of activity form the basis for this.

CIRCUIT DEVELOPMENT

The Circuit development for a wide variety of applications is an integral part of Krüger & Gothe GmbH’s electronics development service. Customers use this service when their own capacities are insufficient. Customers can rely on the many years of extensive experience of Krüger & Gothe GmbH. These development projects are either complete or partial projects. New developments resp. Part developments or for upcoming Redevelopments of existing products. This may be necessary if specifications or technologies are to be changed (e.g. THT to SMD) or if used components are discontinued (last time buy). All of the company’s development work also includes the Experience from various specialist areas, such as the Manufacturing, the Quality assurance and the Materials management of the company.

- Experience with different technologies

- Microcontroller know-how

- Consideration of ESD protection requirements

- Consideration of EMC directives

- Thermal management

- Consideration of production-relevant aspects

- Consideration of test concepts

- Strategic material and manufacturer selection

PRINTED CIRCUIT BOARD DESIGN

The Printed circuit board design has been part of Krüger & Gothe GmbH’s development services for many years. This proven service is very often requested by customers for Optimization of existing layouts or for completely new developments. Existing Gerber data from customers can be used by the experts at Krüger & Gothe GmbH on request. optimized be used to create a Flawless production of raw printed circuit boards to ensure the optimal subsequent manufacturing and testing process of Krüger & Gothe GmbH. This optimization takes place as standard with every new development by Krüger & Gothe GmbH.

- Design according to IPC standards

- Redesign, e.g. THT to SMD technologies

- Data processing according to current standards

- Use of stand. component databases

- Production-optimized design

- Consideration of test concepts

- Holistic cost optimization

- Comprehensive document management

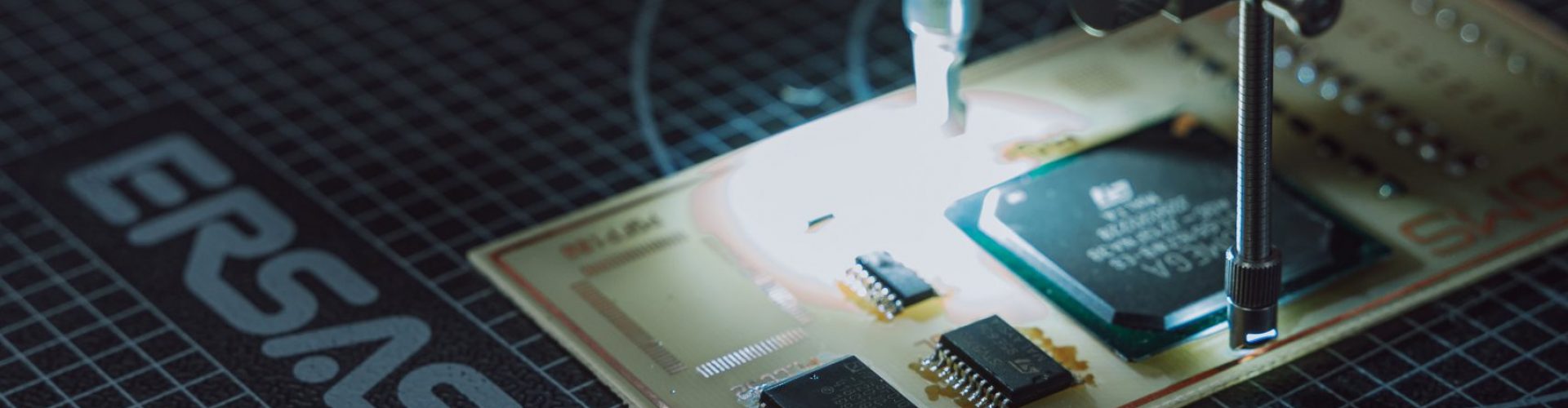

AUDIT CONCEPTS

The aim of Krüger & Gothe GmbH is to, flawless and functional products to the customer. As this requirement cannot be sufficiently ensured by a purely visual inspection, Krüger & Gothe GmbH has Extensive testing expertise built up. The company incorporates this expertise into all development services or designs specific solutions for finished products that are to be produced in the company. Naturally, the solutions are closely coordinated with the customer so that customer requirements can be fully met.

- AOI test

- ICT test

- Boundary scan

- Climatic test

- High voltage test

- Function test

- Optical and mechanical measurements

- Creation of test protocols and certificates

CONSTRUCTION

The strategic goal of the Krüger & Gothe GmbH is to see the customer as System supplier to be able to offer everything from a single source. This also requires specific know-how in the field of mechanical Construction. This allows customers to relieve the limited capacities of their design departments if required. The fact that this work, including the PCB design, is offered from a single source means that a Flawless interaction of the electrical and mechanical requirements. As with all development services, this work also requires good cooperation between the customer and the experts at Krüger & Gothe GmbH.

- Creation of drawings

- Construction of 3D models

- Manufacturing assessment

- Commissioning of tools

- Qualification of suppliers

- Use of 3D measuring equipment

PRODUCT VALIDATION

Some of the customers of the Krüger & Gothe Ltd. pursues the strategy, “everything from a single source” from their trusted electronics service provider (EMS). These customers therefore commission the company to carry out final validation of products that have already been developed. This work requires a high level of product expertise and a sense of responsibility in order not to jeopardize the subsequent market success of the product. Naturally, this work is carried out in close cooperation with the customer and, if necessary, under Involvement of experts from universitieswith whom Krüger & Gothe GmbH has been working intensively for years.

- Development of validation concepts

- Validation of products in the automotive industry

- Networking with universities

- Comprehensive documentation

DEVELOPMENT SUPPORT

One Comprehensive cost analysis of every product is created in the development phase. It therefore makes sense to define the Know-how of succession processes to be incorporated. For this reason, Krüger & Gothe GmbH offers its customers a Qualified development support to.

The company’s experts support the customer’s developers and thus contribute their comprehensive electronics know-how. This ensures that after completion of the development No unnecessary follow-up costs through the Material procurement, production or quality assurance are created. This concept paves the way for a Cost-effective and successful product placed.

- Technological consulting

- Material and manufacturer selection

- Quality consulting

- Optimization of the test concepts

- Total cost optimization

- Production-optimized design

- Series transition to production

- Experienced project management

Krüger & Gothe GmbH specializes in the production of complex electronic products in small, medium and large series. From order management and material procurement to complete production, including comprehensive testing, the company covers the needs of its customers. Many years of experience in all segments of activity form the basis for this.

CIRCUIT DEVELOPMENT

The Circuit development for a wide variety of applications is an integral part of Krüger & Gothe GmbH’s electronics development service. Customers use this service when their own capacities are insufficient. Customers can rely on the many years of extensive experience of Krüger & Gothe GmbH. These development projects are either complete or partial projects. New developments resp. Part developments or for upcoming Redevelopments of existing products. This may be necessary if specifications or technologies are to be changed (e.g. THT to SMD) or if used components are discontinued (last time buy). All of the company’s development work also includes the Experience from various specialist areas, such as the Manufacturing, the Quality assurance and the Materials management of the company.

- Experience with different technologies

- Microcontroller know-how

- Consideration of ESD protection requirements

- Consideration of EMC directives

- Thermal management

- Consideration of production-relevant aspects

- Consideration of test concepts

- Strategic material and manufacturer selection

PRINTED CIRCUIT BOARD DESIGN

The Printed circuit board design has been part of Krüger & Gothe GmbH’s development services for many years. This proven service is very often requested by customers for Optimization of existing layouts or for completely new developments. Existing Gerber data from customers can be used by the experts at Krüger & Gothe GmbH on request. optimized be used to create a Flawless production of raw printed circuit boards to ensure the optimal subsequent manufacturing and testing process of Krüger & Gothe GmbH. This optimization takes place as standard with every new development by Krüger & Gothe GmbH.

- Design according to IPC standards

- Redesign, e.g. THT to SMD technologies

- Data processing according to current standards

- Use of stand. component databases

- Production-optimized design

- Consideration of test concepts

- Holistic cost optimization

- Comprehensive document management

AUDIT CONCEPTS

The aim of Krüger & Gothe GmbH is to, flawless and functional products to the customer. As this requirement cannot be sufficiently ensured by a purely visual inspection, Krüger & Gothe GmbH has Extensive testing expertise built up. The company incorporates this expertise into all development services or designs specific solutions for finished products that are to be produced in the company. Naturally, the solutions are closely coordinated with the customer so that customer requirements can be fully met.

- AOI test

- ICT test

- Boundary scan

- Climatic test

- High voltage test

- Function test

- Optical and mechanical measurements

- Creation of test protocols and certificates

CONSTRUCTION

The strategic goal of the Krüger & Gothe GmbH is to see the customer as System supplier to be able to offer everything from a single source. This also requires specific know-how in the field of mechanical engineering. Construction. This allows customers to relieve the limited capacities of their design departments if required. The fact that this work, including the PCB design, is offered from a single source means that a Flawless interaction of the electrical and mechanical requirements. As with all development services, this work also requires good cooperation between the customer and the experts at Krüger & Gothe GmbH.

- Creation of drawings

- Construction of 3D models

- Manufacturing assessment

- Commissioning of tools

- Qualification of suppliers

- Use of 3D measuring equipment

PRODUCT VALIDATION

Some of the customers of the Krüger & Gothe Ltd. pursues the strategy, “everything from a single source” from their trusted electronics service provider (EMS). These customers therefore commission the company to carry out final validation of products that have already been developed. This work requires a high level of product expertise and a sense of responsibility in order not to jeopardize the subsequent market success of the product. Naturally, this work is carried out in close cooperation with the customer and, if necessary, under Involvement of experts from universitieswith whom Krüger & Gothe GmbH has been working intensively for years.

- Development of validation concepts

- Validation of products in the automotive industry

- Networking with universities

- Comprehensive documentation

DEVELOPMENT SUPPORT

One Comprehensive cost analysis of every product is created in the development phase. It therefore makes sense to define the Know-how of succession processes to be incorporated. For this reason, Krüger & Gothe GmbH offers its customers a Qualified development support to.

The company’s experts support the customer’s developers and thus contribute their comprehensive electronics know-how. This ensures that after completion of the development No unnecessary follow-up costs through the Material procurement, production or quality assurance are created. This concept paves the way for a Cost-effective and successful product placed.

- Technological consulting

- Material and manufacturer selection

- Quality consulting

- Optimization of the test concepts

- Total cost optimization

- Production-optimized design

- Series transition to production

- Experienced project management