ELECTRONICS MANUFACTURING

ORDER MANAGEMENT

Order management at Krüger & Gothe GmbH is an important part of the company. By permanently assigning customers to a member of the order management team, the company ensures the structure “one face to the customer” safe. The company aims to ensure that customers a clear contact person for their ordering needs. Within order management, customer orders are checked, assigned to a Feasibility analysis regarding the points Desired date and Desired quantity and then integrated into the organizational structure for implementation. In the event of deviations from the customer’s wishes, the following are developed in consultation with the customer Solutions which come closest to the customer’s wishes and realistic feasibility. Customers receive a customized Order confirmationto document the agreements. For the different order types The company’s high-performance ERP system provides cross-divisional support for the customer’s business processes. Should it be necessary individual solutions developed and implemented together with the customer. Until the goods are delivered, order management monitors the progress and the on schedule Realization of the orders.

- Individual orders

- Blanket orders with rolling forecast

- Sample orders

- Express service

- Consignment warehouse

- Safety stocks

- Creation of order confirmations

- Central contact for ordering matters

WORK PREPARATION

- Technical and commercial contacts

- Customer quotation calculation

- Preparation of offers

- Qualification of new production technologies

- Project management

- Creation of production concepts

- Creation of parts lists and work plans

- Continuous production optimization

MATERIALS MANAGEMENT

- Individual orders

- Blanket orders with rolling forecast

- Sample orders

- Express services

- Electronic supplier connection

- Consignment stock

- Safety stocks

- Supplier evaluation, qualification & development

- Supplier audits

- Material costing for customer quotations

- Identification of alternative manufacturers

- Last time by Management

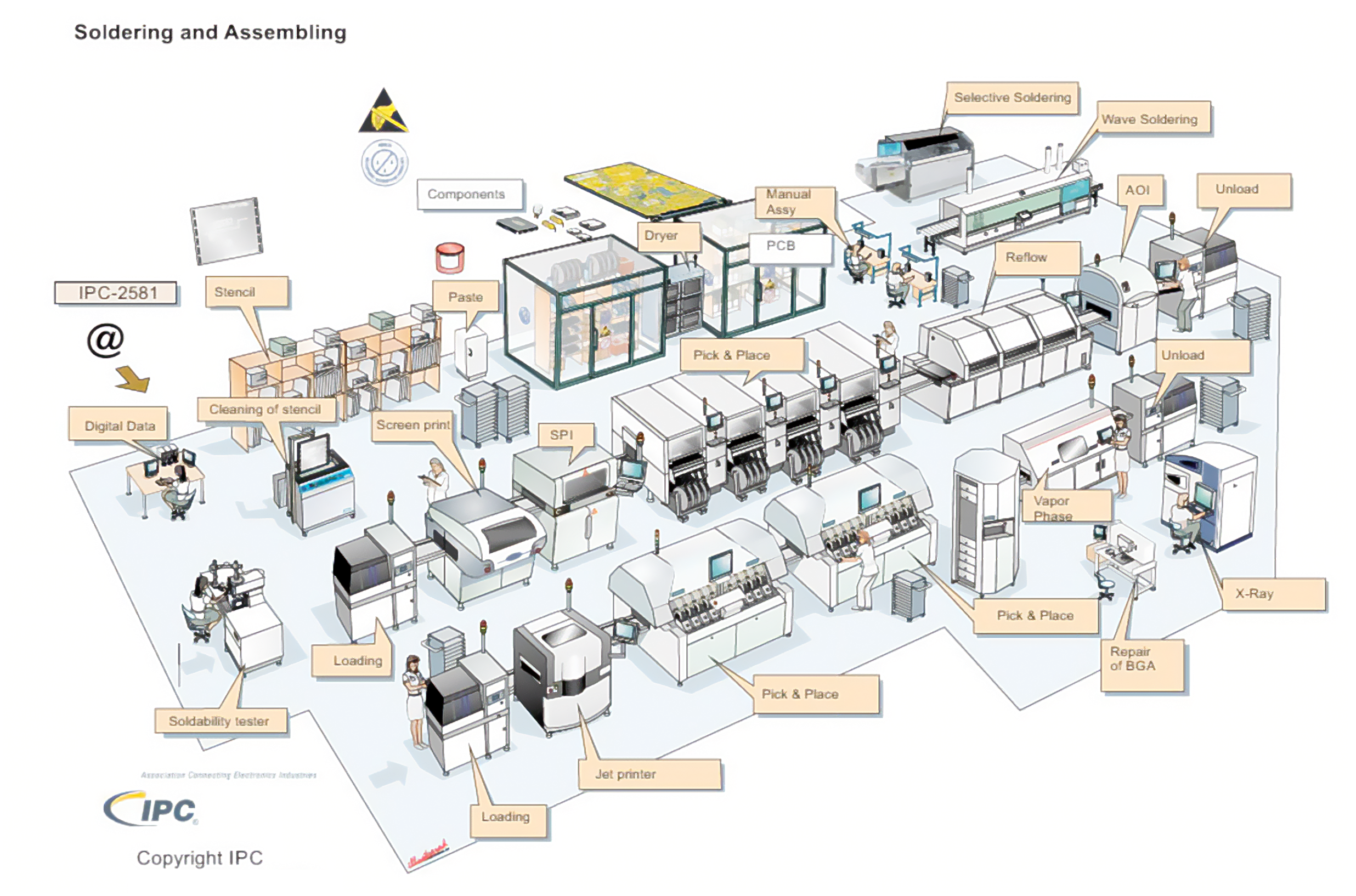

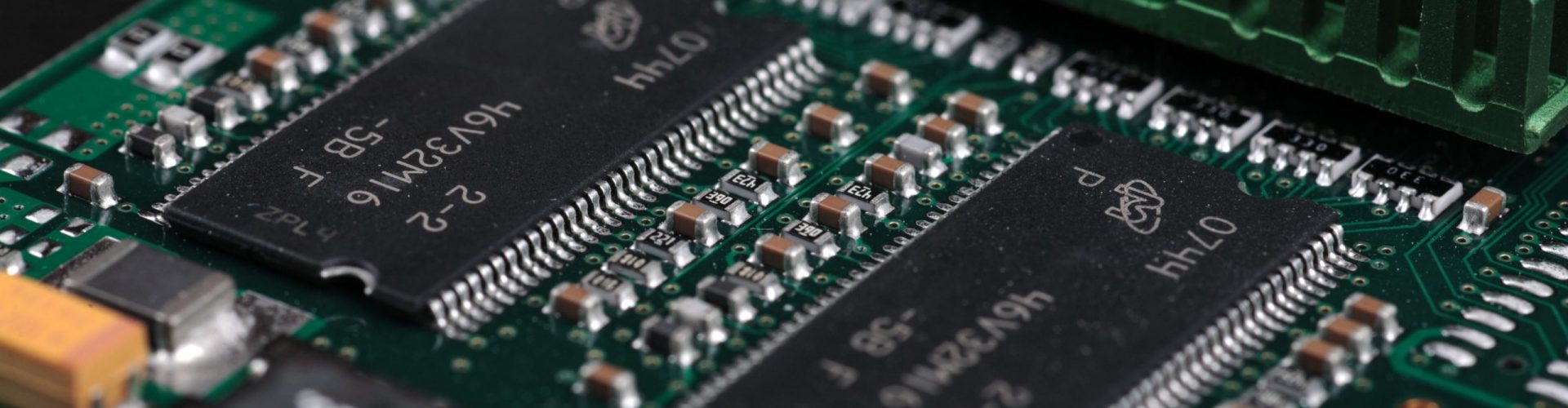

PRODUCTION

- Six SMD lines of the latest generation

- An SMD line for samples and small series

- Various reflow and wave soldering systems — ROHS-compliant overall processes

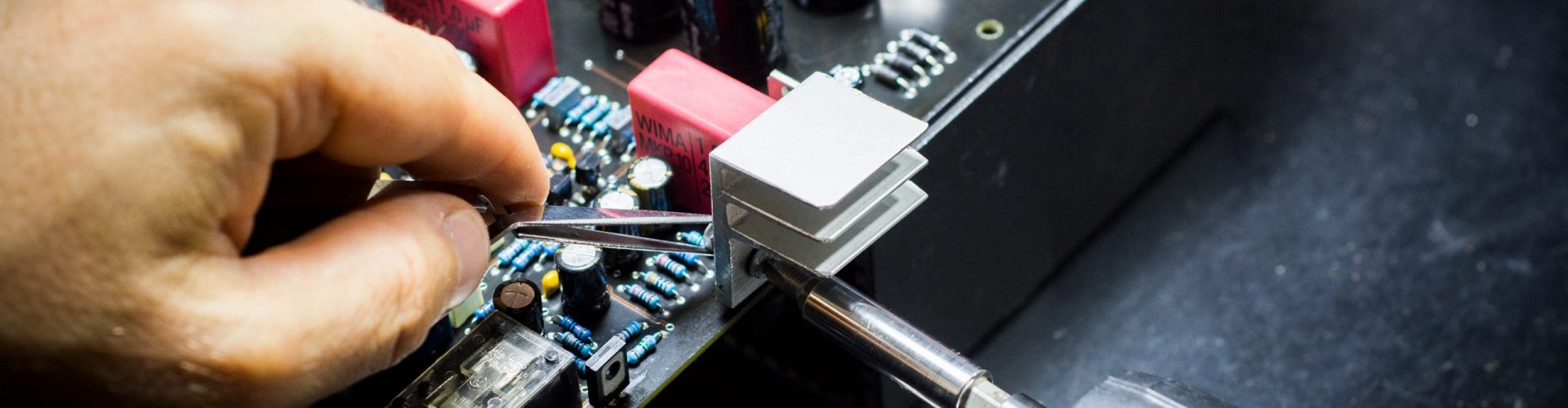

- Manual assembly

- Device installation

- Air conditioning and climate control systems

- Extensive test equipment (AOI systems, in-circuit test, insulation test, functional test, boundary scan, final inspection equipment)

- Endurance devices

- Customized automatic production systems

- Potting and painting systems

- Rework stations for µBGA

- Assembly washing systems

- Laser marking cells

- Burn In

ORDER MANAGEMENT

Order management at Krüger & Gothe GmbH is an important part of the company. By permanently assigning customers to a member of the order management team, the company ensures the structure “one face to the customer” safe.

The company aims to ensure that customers a clear contact person for their ordering needs. Within order management, customer orders are checked, assigned to a Feasibility analysis regarding the points Desired date and Desired quantity and then integrated into the organizational structure for implementation.

In the event of deviations from the customer’s wishes, the following are agreed with the customer Solutions which come closest to the customer’s wishes and realistic feasibility. Customers receive a customized Order confirmationto document the agreements. For the different order types The company’s high-performance ERP system provides cross-divisional support for the customer’s business processes. Should it be necessary individual solutions developed and implemented together with the customer.

Until the goods are delivered, order management monitors the progress and the on schedule Realization of the orders.

- Individual orders

- Blanket orders with rolling forecast

- Sample orders

- Express service

- Consignment warehouse

- Safety stocks

- Creation of order confirmations

- Central contact for ordering matters

WORK PREPARATION

- Technical and commercial contacts

- Customer quotation calculation

- Preparation of offers

- Qualification of new production technologies

- Project management

- Creation of production concepts

- Creation of parts lists and work plans

- Continuous production optimization

MATERIALS MANAGEMENT

- Individual orders

- Blanket orders with rolling forecast

- Sample orders

- Express services

- Electronic supplier connection

- Consignment stock

- Safety stocks

- Supplier evaluation,

‑qualification & development - Supplier audits

- Material costing for customer quotations

- Identification of alternative manufacturers

- Last time by Management

PRODUCTION

- Six SMD lines of the latest generation

- An SMD line for samples and small series

- Various reflow and wave soldering systems — ROHS

compliant overall processes - Manual assembly

- Device installation

- Air conditioning and climate control systems

- Extensive testing equipment (AOI systems,

In-circuit test, insulation test, function test,

boundary-scan, final inspection equipment) - Endurance devices

- Customized automatic

Production facilities - Potting and painting systems

- Rework stations for µBGA

- Assembly washing systems

- Laser marking cells

- Burn In